Identifying & Overcoming Supply Chain Challenges

A TAB WHITEPAPER ON THE CAUSES AND SOLUTIONS RELATED TO SUPPLY CHAIN DISRUPTIONS, WHETHER TRIGGERED BY A GLOBAL PANDEMIC OR OTHER NEGATIVE MARKET FACTORS.

Business owners received a master class in the last several years on how supply chain issues, seemingly beyond their control, can negatively impact their ability to operate their companies and service their customers.

It is easy to point fingers at COVID-19 for disrupting global supply chains, but that doesn’t paint an entirely accurate picture of recent dynamics. While lockdowns and Work From Home protocols certainly played huge roles in the supply chain challenges of 2020 and beyond, other arguably more avoidable factors also contributed to a break in the free flow of goods and resources.

Civil unrest, wildfires and natural disasters like cyclones and flooding all played a part in recent supply chain woes, leaving shelves empty and businesses unable to meet demand.

In this TAB Business Whitepaper, we explore a number of common causes related to supply chain disruptions and then share hands-on approaches business owners can take to overcome them.

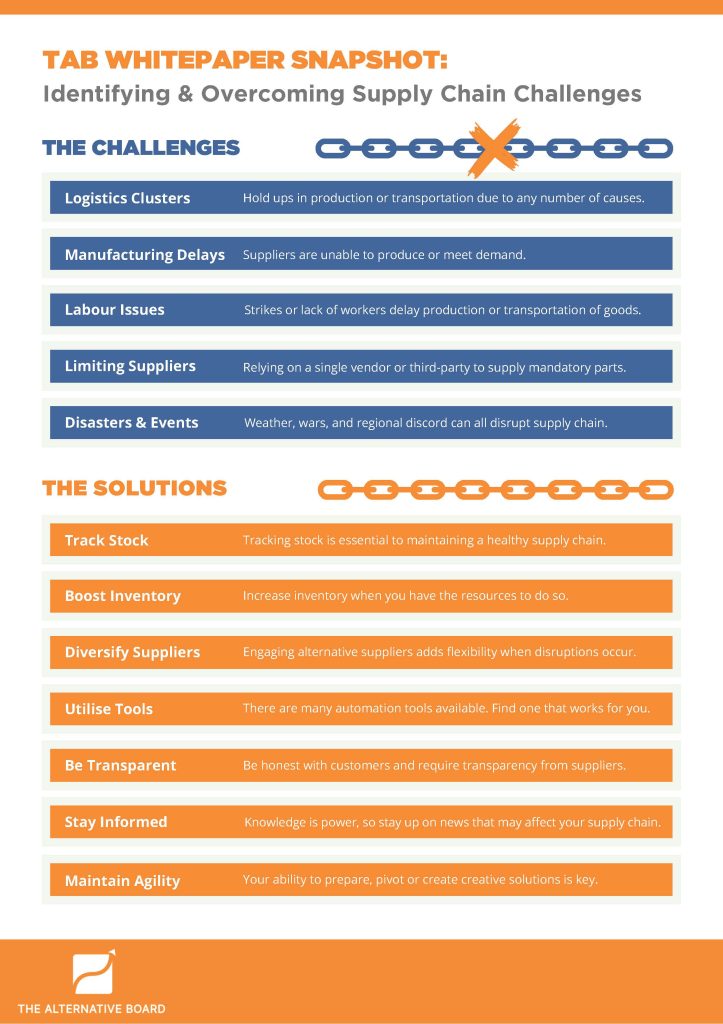

THE CHALLENGES

Numerous factors commonly play a part in every broken supply chain. Supply chain issues can be very complex and causations seemingly ambiguous, but many business owners share common challenges.

Logistics Clusters

Throughout the pandemic, news outlets shared shocking photographs and heatmaps of global ports jammed with freighters sitting idle and unable to offload their cargo.

The supply chain will always remain vulnerable to transit hub issues and other logistics disruptions. Natural disasters, labor strikes, wars, embargos and so many other negative factors can impact the steady flow of global goods.

While pandemic-related logistics disruptions continue to wane, issues like the war in Ukraine and OPEC’s cuts to oil production continue to upset the worldwide supply chain. In this global economy, even smaller regional disrupters have the potential to create a formidable ripple effect.

Manufacturing Delays

During a supply chain shortage, manufacturers are faced with the same struggle to acquire parts and raw materials as everyone else, causing often devastating delays in production.The manufacturing industry is commonly the first to take the hit in a negative supply chain scenario, and is often the catalyst for the broadening of shortages and backlogs.Widespread production delays throughout the pandemic had a massive impact on the economy, inflation, and customers’ ability to obtain vital or lifesaving goods (like PPE), not to mention manufacturers’ prognosis for long- term survival.

SUPPLY CHAIN: THE CHALLENGES

Workforce & Labour Issues

You don’t need to be an employment expert to understand that labour dynamics have changed drastically since 2020. Spurred on by pandemic lockdowns and Safer At Home work protocols, the global workforce has changed its employment preferences regarding nearly every aspect of engagement. And it all comes at a price, both to a business’s profitability and its ability to deliver its cornerstone goods and services.

While the inner workings of most businesses combatting staffing issues during the pandemic remained hidden behind office walls and C-suites, the supply chain impact and fallout from the lack of labour was witnessed firsthand by most customers engaging in the hospitality sectors.

Notably, the hotel industry almost entirely ditched obligatory housekeeping services due to a substantial lack of staff and skyrocketing labour costs. Restaurants shortened operational hours, often not because of a dearth in diners, but rather a shortage of chefs and waitstaff.

Employee acquisition and retention appear to be slowly improving to pre-pandemic levels, but the workforce will always possess collective power and the ability to substantially affect global supply chains – whether indirectly, like the hospitality workers, or by design, as seen in organised labour strikes.

Limiting Suppliers & Partnerships

Many businesses make a huge tactical supply chain management error by limiting partnerships to a single third-party provider, often driven by cost alone.

Another common strategic misstep is selecting multiple suppliers that are all centralised in a single country or region. This approach potentially leaves an organisation’s entire supply chain vulnerable to negative location-related factors including civil unrest, political interference, and natural disasters, to name a few.

By failing to identify alternative trading partnerships, business owners leave their companies extremely vulnerable to a single supplier’s ability (or lack thereof) to deliver mandatory goods on time or really at all.

Other Contributing Factors

Identifying the root causes of a broken supply chain can be tricky, as many factors can combine to create the proverbial perfect storm. Poor spend transparency, lack of investment in supply chain management technology, and all kinds of market instability can wreak havoc on access to necessary resources.

THE SOLUTIONS

Fortifying & Future-Proofing Your Supply Chain

While the pandemic’s extended impact on supply chains was nearly unprecedented in both scope and scale, businesses’ vulnerability to disruptions should be considered a sustained and pressing issue due to the global economy and an ever-expanding world market.

In fact, the McKinsey Global Institute reported that individual companies experience on average one supply chain disruption lasting one to two months every 3.7 years. And the financial fallout can be devastating.

There is, however, a great deal of empirical data that supports the efficacy of enhanced supply chain management efforts. Automobile giant Toyota overcame massive supply chain vulnerabilities after the 2011 Tohoku earthquake and tsunami dramatically reduced production for almost six months. The carmaker overhauled its manufacturing strategy, decentralised supplier chains, and assessed vendor weaknesses. When another earthquake hit the area five years later, production was only delayed two weeks.

Creating or reinventing your Supply Chain Strategy to overcome future disruptions should really be a key aspect of your overall business and growth strategies.

Track Stock

Maintaining accurate inventory reports is essential to effective supply chain management. Tracking stock gives business owners the ability to detect problems early on, creates efficiencies in ordering, reduces the potential for theft and loss, and helps provide better customer service.

Supply chain shortages and disruptions are inevitable, so consistently track stock to mitigate future risk.

Boost Inventory

Identifying & Overcoming Supply Chain Challenges White Paper

While some businesses simply don’t have the luxury of investing extra dollars in backup inventory, not to mention the extra space and muscle required to do so, there are notable budget-conscious ways to boost inventory.

- Purchase as much of your key products as you can afford.

- Take advantage of discounts by stocking up at a reduced cost.

- Create or lease extra storage space.

- Budget for expanding inventory.

Diversify Suppliers

One of the biggest mistakes business owners make in their supply chain strategy is to rely on a single supplier.

Research alternative sources that are geographically diverse. This approach helps protect your supply chain from regional disturbances, while also providing better opportunity for competitive pricing.

Be creative. Flexibility in product requirements expands your supplier options.

Utilise Supply Chain Management Tools

Supply chain management (SCM) software helps efficiently manage the flow of inventory, ordering, shipping, and a multitude of other aspects related to supply chain. And SCM is not just for the big guys; many small businesses can benefit from the often scalable software.

Be Transparent & Forthcoming

They say honesty is the best policy and this is certainly true when dealing with supply chain disruptions. One positive thing to come from the pandemic is wider understanding and perhaps forgiveness surrounding empty shelves or lack of stock.

Post disruptions or delays on your company website. Have your sales reps or other key players reach out to regular customers to give them a heads up and provide options and ETAs.

Stay Informed

While supply chain issues can catch a business off-guard, many disruptions are rather predictable. Factors like political unrest, weather events, and natural disasters are commonly covered by news media outlets. Consider creating a Google alert related to supplier regions and potential threats against your supply chain. Also, be sure to keep up on trends and news related to your industry.

Maintain Agility

Supply chain agility refers to a business’s ability to efficiently pivot based on changes in market volatility, supply chain disruptions, and even evolving customer preferences.

It also includes the ability to foresee, avoid, and rebound from supply chain disruptions.

No business is immune to broken supply chains. But by implementing a strong, strategic, and flexible supply chain strategy, your chances of weathering even the worst disruptions are dramatically increased.